This manual provides essential guidance for the installation, operation, and maintenance of the M92 Servo Motor, ensuring optimal performance and safety in industrial applications.

1.1 Overview of the M92 Servo Motor

The M92 Servo Motor is a high-torque AC servomotor designed for industrial applications, particularly in sewing machines, robotics, and automation. Known for its energy efficiency, precision, and programmability, it is part of the Juki DDL series. The motor features a compact design, reduced vibration, and high stiffness, making it ideal for demanding tasks. With a 450W power output, it delivers robust performance while minimizing power consumption. Its compatibility with advanced control systems like the SC-920 ensures seamless integration and precise operation. The M92 is engineered for reliability and customization, offering tailored solutions for specific industrial needs, making it a vital component in modern manufacturing and production environments.

1.2 Importance of the Instruction Manual

The instruction manual is crucial for understanding the M92 Servo Motor, ensuring safe and efficient operation. It provides detailed guidance on installation, configuration, and troubleshooting, minimizing risks of damage or malfunction. The manual includes essential safety precautions, environmental considerations, and electrical guidelines to prevent hazards. It also offers step-by-step instructions for optimal setup and maintenance, ensuring prolonged motor lifespan. By following the manual, users can maximize the motor’s performance, customize settings for specific tasks, and integrate it seamlessly with control systems. Adhering to the manual is vital for achieving the full potential of the M92 Servo Motor in industrial applications.

Technical Specifications of the M92 Servo Motor

The M92 is a 450W high-torque AC servomotor designed for industrial sewing, offering energy efficiency, precision, and compatibility with advanced control systems like the SC-920.

2.1 Design and Features

The M92 Servo Motor features a compact and lightweight design, with a 30% smaller control box compared to previous models. It is part of Juki’s DDL series, engineered for high-torque performance and energy efficiency. The motor offers reduced vibration and precise control, making it ideal for industrial sewing machines. Its design emphasizes durability and reliability, with a focus on minimizing environmental impact through energy-saving technologies. The M92 is tailored for demanding tasks in apparel manufacturing, providing consistent and efficient operation. Its advanced AC servo technology ensures smooth power delivery, while its programmable functionality allows for customized performance in various industrial applications.

2.2 Performance Capabilities

The M92 Servo Motor delivers high-torque performance with a power output of 450W, ensuring robust operation for demanding industrial applications. Its advanced AC servo technology provides smooth and consistent power delivery, minimizing vibrations and noise. Designed for precision, the motor offers accurate speed and position control, making it ideal for heavy-duty sewing tasks. The M92 supports high-volume production environments with reliable and efficient performance. Its energy-efficient design reduces power consumption while maintaining productivity, aligning with eco-friendly practices. The motor’s performance capabilities are further enhanced by its compatibility with advanced control systems, ensuring seamless integration and optimal productivity in industrial sewing operations.

2.3 Compatibility with Industrial Sewing Machines

The M92 Servo Motor is specifically designed for seamless integration with industrial sewing machines, particularly Juki’s DDL series, such as the DDL-8700-7. Its compact design and high-torque output make it ideal for demanding sewing tasks, ensuring precise control and enhanced productivity. The motor is fully compatible with advanced control systems like the SC-920 and CP-18 panel, enabling precise monitoring and operation. Its integration with these systems simplifies setup and ensures efficient performance. The M92’s compatibility with industrial sewing machinery makes it a vital component for modern apparel production, offering reliable operation and tailored functionality for various stitching requirements and fabric types.

Safety Precautions and Guidelines

Avoid exposing the M92 Servo Motor to water, flammable substances, or excessive vibration. Ensure proper grounding, use insulated tools, and follow manual guidelines to prevent electrical hazards.

3.1 General Safety Instructions

Always ensure the M92 Servo Motor is installed and operated in a safe environment. Proper grounding is essential to prevent electrical hazards. Avoid exposing the motor to water, flammable gases, or corrosive substances. Never touch electrical components with wet hands, and use insulated tools during installation. The motor should be mounted on a stable, non-flammable surface, away from excessive vibration or shock. Ensure proper ventilation and avoid extreme temperatures or humidity. Read the manual thoroughly before starting any operation. Follow all safety guidelines to prevent accidents and ensure the motor’s longevity. Regular inspections of wiring and connections are crucial for safe operation.

3.2 Environmental and Handling Precautions

Handle the M92 Servo Motor with care to prevent damage. Avoid exposing it to water, flammable gases, or corrosive substances. Install it on a non-flammable, stable surface, away from excessive vibration or shock. Ensure the environment is well-ventilated and free from extreme temperatures and humidity. Store the motor in a dry, cool place when not in use. Avoid touching electrical components with wet hands and always use insulated tools. Proper handling and storage are essential to maintain performance and longevity. Follow the manual’s guidelines for environmental precautions to ensure safe and efficient operation of the M92 Servo Motor.

3.3 Electrical Safety Measures

Ensure the M92 Servo Motor and control systems are properly grounded to prevent electrical hazards. Use a grounded power supply and avoid incorrect voltage connections. Never touch electrical components with wet hands to avoid shock. Keep the motor and control box away from flammable materials. Regularly inspect wiring for damage or wear. Use only approved cables and connectors to maintain safety standards. Always follow the manual’s electrical safety guidelines to protect against short circuits and ensure reliable operation. Proper grounding is crucial for safe and efficient performance of the M92 Servo Motor.

Installation and Setup of the M92 Servo Motor

Follow the manual’s guidelines for proper installation, ensuring secure mounting, correct wiring, and precise configuration. Perform a test run to confirm smooth operation and adjust settings as needed.

4.1 Pre-Installation Checklist

Before installing the M92 Servo Motor, ensure compatibility with your system and review the manual. Inspect the motor and control box for damage. Verify all necessary components, such as mounting brackets and cables, are included. Check the power supply matches the motor’s specifications (e.g., 230V AC, 3-phase, 50/60 Hz). Ensure the installation area is clean, dry, and free from vibrations. Proper grounding is essential to prevent electrical hazards. Use insulated tools to avoid shock. Familiarize yourself with the wiring diagram and parameter settings in the manual. Ensure the environment is non-flammable and well-ventilated. Follow all safety guidelines to guarantee a safe and efficient installation process.

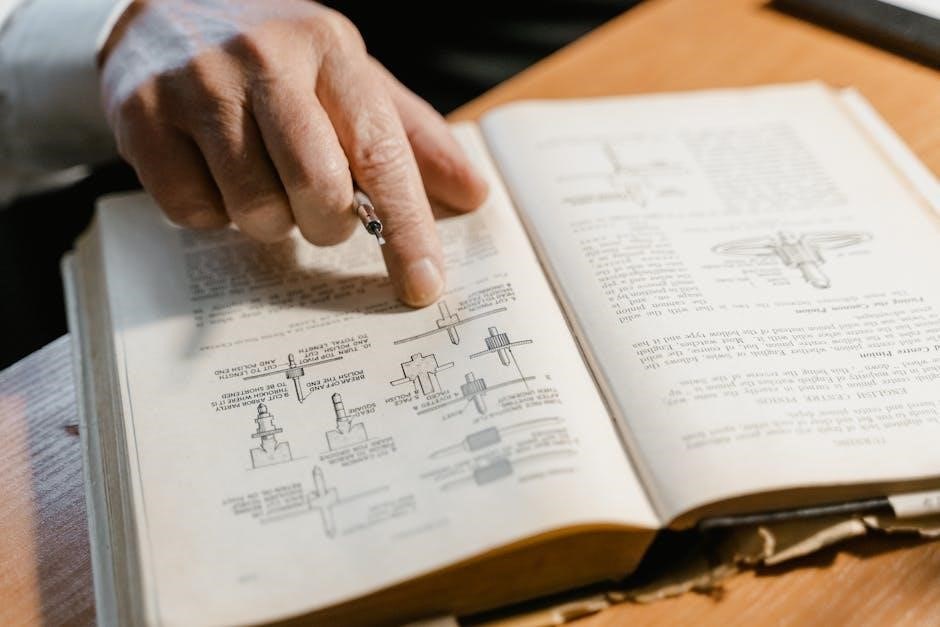

4.2 Mounting the Motor

Mount the M92 Servo Motor on a stable, non-flammable surface, ensuring it is level and secure. Use the provided mounting brackets and follow the manual’s torque specifications to avoid damage. Properly align the motor shaft with connected machinery to ensure accurate operation. Tighten all screws evenly and verify the motor is level to prevent vibration. Ensure the installation area is free from flammable materials and excessive noise. Refer to the manual for detailed diagrams and alignment procedures. Proper mounting is critical for optimal performance, safety, and longevity of the motor. Always follow the manufacturer’s guidelines for secure and precise installation.

4.3 Wiring and Connections

Connect the M92 Servo Motor using the provided 4-wire cable, ensuring correct wire connections for power and signal. Connect the motor’s power wires to the control box’s corresponding terminals and the signal wires for encoder feedback. Verify the power supply matches the motor’s specifications (e.g., 230V AC, 3-phase, 50/60 Hz). Proper grounding is essential to prevent electrical noise or damage. Follow the manual’s wiring diagram and parameter settings for accurate configuration. Avoid incorrect connections, as they may result in malfunction or damage. Always refer to the manual for specific instructions and safety precautions. Proper wiring ensures reliable operation and system integrity.

4.4 Initial Configuration and Parameter Settings

After wiring, power on the M92 Servo Motor and load default settings from the control box or manual. Configure parameters like torque, speed, and position limits using the control panel or software. Ensure encoder calibration is accurate for precise control. Refer to the manual for specific parameter settings and configuration steps. Test the motor under controlled conditions to verify smooth operation and adjust settings as needed. Proper initial setup ensures optimal performance, safety, and longevity. Always follow the manual’s guidelines to avoid configuration errors and ensure reliable operation.

Operating the M92 Servo Motor

The M92 Servo Motor operates in speed and torque modes, enabling precise control for industrial sewing applications. Programming and monitoring ensure optimal performance and efficiency.

5.1 Starting the Motor

To start the M92 Servo Motor, ensure all connections are secure and properly configured. Power on the system and load the motor’s default settings from the control box or manual. Perform a test run to verify smooth operation, checking for any vibrations or unusual noises. Adjust parameters like speed and torque as needed for optimal performance. Ensure encoder calibration is accurate for precise control. Refer to the manual for specific startup procedures and safety precautions, such as emergency stop protocols. Proper initialization ensures reliable operation and prevents potential damage. Always follow the manual’s guidelines for safe and efficient motor startup.

5.2 Speed and Torque Control Modes

The M92 Servo Motor operates in multiple control modes, including speed and torque control, allowing precise adjustment for various industrial applications. Speed mode enables variable velocity settings, while torque mode provides consistent force application. These modes can be programmed to suit specific tasks, optimizing productivity in sewing operations. Advanced settings, such as acceleration and deceleration rates, can be configured to minimize vibration and ensure smooth operation. Real-time adjustments allow fine-tuning of parameters during operation, enhancing performance accuracy. The motor’s programmability enables tailored configurations, making it adaptable to diverse industrial needs while maintaining high efficiency and reliability. Proper mode selection ensures optimal performance and energy efficiency in demanding environments.

5.3 Programming and Customization Options

The M92 Servo Motor offers extensive programming and customization options, allowing users to tailor its performance to specific industrial tasks. Through advanced software tools, operators can define precise parameters such as speed, torque, and position limits. Customizable acceleration and deceleration profiles reduce mechanical stress, enhancing equipment longevity. Users can store predefined settings for repetitive tasks, ensuring consistent operation across various applications. The motor’s programmable functionality also supports the creation of complex stitching patterns in sewing machines, optimizing productivity. Real-time adjustments enable fine-tuning during operation, while data logging and analysis tools provide insights for further customization. These features make the M92 Servo Motor highly adaptable and efficient for diverse industrial needs, ensuring precise and reliable performance in demanding environments.

5.4 Monitoring and Adjusting Performance

Monitoring and adjusting the M92 Servo Motor’s performance is essential for maintaining optimal operation. Users can utilize advanced control panels, such as the SC-920, to track real-time data like speed, torque, and position. The motor’s integrated encoder provides precise feedback, enabling accurate performance monitoring. Adjustments can be made through the control system or external software, allowing for fine-tuning of parameters to enhance efficiency. Data logging capabilities help identify trends and potential issues, enabling proactive maintenance. Regular performance checks ensure the motor operates within specified limits, minimizing wear and tear. By adhering to the manual’s guidelines, users can optimize the M92 Servo Motor’s performance for their specific industrial applications, ensuring reliability and productivity.

Maintenance and Troubleshooting

Regular maintenance ensures the M92 Servo Motor’s longevity and performance. Inspect wiring, clean components, and check for wear. Refer to the manual for troubleshooting common issues promptly.

6.1 Regular Maintenance Procedures

Regular maintenance is essential to ensure the M92 Servo Motor operates efficiently and reliably. Inspect the motor and control systems periodically for signs of wear or damage. Clean the motor and its surroundings to prevent dust buildup, which can affect performance. Lubricate moving parts as recommended in the manual, but avoid over-lubrication. Check the wiring and connections for any damage or loose contacts, ensuring they are secure and properly insulated. Verify the motor windings for integrity and test the encoder feedback for accuracy. Perform these procedures with the motor powered off and use insulated tools to prevent electrical shock. Follow the manual’s guidelines for routine checks to maintain optimal functionality and extend the motor’s lifespan.

6.2 Common Issues and Solutions

Common issues with the M92 Servo Motor include wiring faults, improper parameter settings, and environmental exposure. For wiring issues, check connections for damage or misalignment and ensure proper grounding. If the motor fails to start, verify power supply and control signals. Incorrect parameter settings can cause performance instability; refer to the manual for reset procedures. Environmental factors like moisture or extreme temperatures may lead to malfunction; ensure the motor is operated in recommended conditions. Regularly inspect and clean the encoder for accurate feedback. Addressing these issues promptly ensures reliable operation and extends the motor’s lifespan. Always follow the manual’s troubleshooting guidelines for effective resolution.

6.3 Advanced Troubleshooting Techniques

For advanced troubleshooting, use diagnostic tools to analyze motor feedback and control signals. Check the encoder for accurate position data and ensure proper alignment. If issues persist, inspect the servo amplifier and motor connections for signal integrity. Perform a factory reset and reconfigure parameters to eliminate software-related faults. Test the motor in manual mode to isolate control system errors. Regularly update firmware to resolve known issues and improve performance. Consult the manual for detailed diagnostic procedures and utilize advanced testing equipment for precise fault identification. These techniques ensure comprehensive resolution of complex problems, ensuring optimal motor performance and reliability in demanding applications.

Energy Efficiency and Programmability

The M92 Servo Motor features advanced energy-saving technologies and programmable functionality, enabling precise customization and enhancing productivity while reducing power consumption and operational costs effectively.

7.1 Energy-Saving Features

The M92 Servo Motor incorporates advanced energy-saving technologies, reducing power consumption during operation and standby. Its compact control box, 30% smaller and lighter, enhances resource efficiency and lowers electricity costs. Designed with eco-friendly practices in mind, the motor aligns with global sustainability goals while maintaining high productivity. By minimizing energy usage without compromising performance, the M92 supports environmentally responsible operations, making it an ideal choice for industries prioritizing energy efficiency and reduced environmental impact. These energy-saving features ensure cost-effectiveness and contribute to a greener manufacturing process, enhancing the motor’s appeal in modern industrial applications.

7;2 Programmable Functionality

The M92 Servo Motor offers extensive programmable functionality, allowing users to customize its operation for specific tasks. Through advanced software tools, operators can define precise parameters such as speed, torque, and position, optimizing performance for various applications. The motor supports programmable acceleration and deceleration profiles, which reduce mechanical stress and extend equipment lifespan. Additionally, users can create and store custom profiles for different operations, ensuring tailored performance in industrial sewing applications. This programmability enhances efficiency and accuracy, enabling the M92 to adapt to diverse production needs while maintaining high reliability and productivity. Such customization capabilities make the M92 a versatile and essential component in modern manufacturing systems.

7.3 Integration with Control Systems

The M92 Servo Motor seamlessly integrates with advanced control systems, such as the SC-920 control box and CP-18 panel, ensuring precise monitoring and control. Its compatibility with these systems allows for efficient operation and real-time adjustments. The motor connects via a 4-wire cable, with proper grounding essential to prevent electrical interference. This integration enables users to access advanced features like speed and torque control, as well as programmable parameters, directly through the control interface. The M92’s design ensures smooth communication with industrial sewing machinery, enhancing productivity and reducing downtime. Its compatibility with Juki’s advanced control systems makes it a reliable choice for modern manufacturing environments, offering a user-friendly experience and optimal performance.

Compatibility and Integration

The M92 Servo Motor is designed for seamless integration with industrial sewing machinery and advanced control systems, ensuring compatibility and efficient operation in various manufacturing environments.

8.1 Compatible Control Systems

The M92 Servo Motor is fully compatible with advanced control systems such as the SC-920 control box and CP-18 panel, ensuring seamless integration and precise operation. Its design allows for easy connection to these systems, facilitating efficient setup and energy-saving features. The motor works in conjunction with these control systems to enable precise control and monitoring, making it a reliable choice for industrial applications. Proper integration with control systems is essential for maximizing the motor’s capabilities and maintaining productivity. The M92’s compatibility ensures optimal performance and simplifies the setup process for users, making it a vital component in modern industrial sewing solutions.

8.2 Integration with Sewing Machinery

The M92 Servo Motor seamlessly integrates with industrial sewing machinery, enhancing productivity and precision. Designed for compatibility with Juki sewing machines, such as the DDL-8700-7, it ensures smooth operation and reduced vibration. Its compact design and high torque make it ideal for demanding sewing tasks, while its energy-efficient features minimize power consumption. The motor connects easily to sewing machinery, offering precise control over stitching and fabric handling. Its programmable functionality allows customization for specific sewing operations, ensuring efficient performance across various fabrics and stitching requirements. This integration enables optimal synchronization between the motor and sewing machinery, delivering high-quality results in industrial apparel production.

8.3 Compatibility with Advanced Control Panels

The M92 Servo Motor is designed to integrate seamlessly with advanced control panels, such as the SC-920 and CP-18, ensuring precise control and monitoring. Its compatibility with these systems allows for synchronized operation, enabling real-time adjustments and optimal performance. The motor supports advanced control features, including speed, torque, and position adjustments, which can be easily managed through the control panel interface. This integration enhances productivity and reduces energy consumption, making it a reliable choice for industrial sewing applications. Proper connection and configuration with control panels are essential for unlocking the motor’s full potential and achieving efficient, high-quality results in demanding environments.

9.1 Summary of Key Points

The M92 Servo Motor is a high-torque AC servomotor designed for industrial sewing machines, offering energy efficiency, precision, and programmability. Part of Juki’s DDL series, it enhances productivity while reducing power consumption. The manual provides comprehensive guidance on installation, operation, and maintenance, ensuring optimal performance and safety. Key features include high torque, compact design, and compatibility with advanced control systems. The motor’s programmable functionality allows customization for specific tasks, ensuring efficient operation across various applications. Adhering to the manual is crucial for maximizing the motor’s capabilities, minimizing risks, and prolonging its lifespan. Proper setup, safety protocols, and regular maintenance are emphasized for reliable performance.

9.2 Importance of Adhering to the Manual

Adhering to the M92 Servo Motor Instruction Manual is crucial for ensuring safe, efficient, and reliable operation. The manual provides detailed safety precautions to prevent hazards and maintain operational integrity. By following the guidelines, users can optimize the motor’s performance, energy efficiency, and productivity. Proper setup, parameter configuration, and maintenance procedures are essential to avoid malfunctions and extend the motor’s lifespan. Additionally, adhering to the manual ensures compliance with environmental and safety standards, minimizing risks and enhancing overall operational excellence. Regular maintenance and troubleshooting procedures outlined in the manual further contribute to sustained performance and longevity of the M92 Servo Motor.